Introduction to Machine Vision

Machine vision, a critical element of automation and artificial intelligence, refers to the technology and methods used to provide imaging-based automatic inspection and analysis. This technology has become increasingly important across various sectors, including manufacturing, healthcare, and logistics. By enabling machines to interpret visual information akin to human vision, machine vision plays a pivotal role in enhancing operational efficiency and reliability. It helps organizations automate complex processes, eliminate human error, and uphold quality standards. Delving deeper into machine vision reveals its sophisticated components and widespread applications.

Defining Machine Vision

Machine vision encompasses a variety of technologies that allow electronic systems to interpret visual data. This can include anything from simple bar code scanning to complex analysis of images for quality assurance in manufacturing. Typically, machine vision systems consist of cameras, lighting, processing hardware, and software that collectively automate the task of visual inspection. Central to this field is the ability to capture images, analyze them, and make informed decisions based on the visual data.

Historical Development and Technology

The roots of machine vision can be traced back to the early 1960s when researchers began exploring how computers could process images. Early systems were limited by the technology of their time, lacking the computational power and robust algorithms available today. However, with advancements in camera technology, image processing techniques, and artificial intelligence, machine vision has quickly evolved. Modern systems employ techniques like pattern recognition, deep learning, and neural networks to achieve high accuracy and speed in various applications.

Importance in Various Industries

Machine vision’s application is vast, impacting several industries. In manufacturing, it ensures products meet quality standards by detecting defects early in the production line. In healthcare, machine vision systems assist in diagnostic processes, analyzing medical imaging data with exceptional precision. Other applications include food safety inspections in agriculture and logistics, where it streamlines sorting and tracking processes. The integration of machine vision not only increases efficiency but also enhances reliability and safety across these sectors.

Core Components of Machine Vision Systems

Cameras and Sensors in Machine Vision

At the heart of any machine vision system are cameras and sensors. These devices capture images to be processed and analyzed. There are various types of cameras available, such as area cameras, line scan cameras, and 3D cameras, each suitable for different applications. The choice of camera typically depends on the specific requirements of the task, such as the need for high resolution in quality control or the capacity to capture images at high speeds in manufacturing scenarios.

Software Algorithms for Image Processing

After capturing images, the next critical step involves processing the visual data using sophisticated software algorithms. Image processing software enhances image quality, enabling the identification of relevant features and patterns. Common processing tasks include image enhancement, thresholding, edge detection, and pattern recognition. The integration of artificial intelligence and machine learning into these algorithms has significantly improved the ability of these systems to learn and adapt over time, leading to enhanced performance metrics such as accuracy and speed.

Lighting and Optics Considerations

The effectiveness of machine vision systems is heavily influenced by lighting and optical conditions. Adequate lighting is crucial as it affects image clarity and contrast. Various lighting techniques are employed, such as backlighting, side lighting, and diffuse lighting, each tailored to the specific application requirement. Additionally, optics, including lenses and filters, play a significant role in determining the system’s capability to capture sharp and accurate images. Careful calibration between these components ensures optimum results in image quality, thereby enhancing the overall effectiveness of machine vision systems.

Applications of Machine Vision

Quality Control and Defect Detection

The application of machine vision in quality control has revolutionized the manufacturing process by automating defect detection. Machines equipped with vision systems can identify inconsistencies and defects in real time, allowing for immediate corrective actions. For instance, in automotive manufacturing, machine vision systems inspect components for flaws, ensuring each part meets strict quality specifications. This not only reduces waste but also enhances customer satisfaction by delivering products that adhere to the highest quality standards.

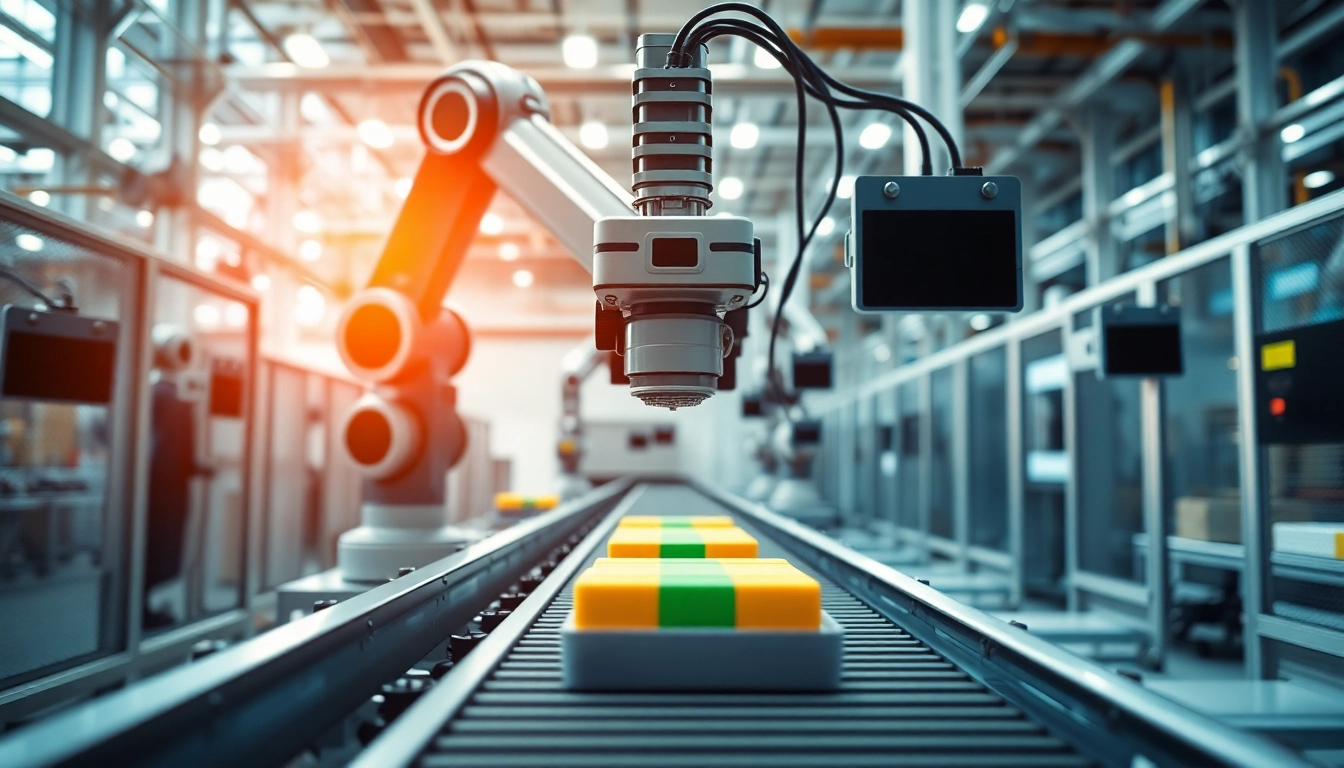

Automation in Manufacturing

Machine vision systems are at the forefront of the push towards automation in manufacturing environments. These systems facilitate various tasks, such as assembly verification and material handling, making production lines more efficient and less prone to human error. For example, robots equipped with machine vision can precisely assemble components, verifying alignment and orientation in real-time. This dramatically increases throughput and reduces reliance on human labor for repetitive tasks.

Healthcare and Biometric Systems

In the healthcare sector, machine vision technology enhances diagnostic accuracy and patient safety. For instance, systems using machine vision can analyze X-rays and MRIs, identifying anomalies that may be overlooked by the human eye. Additionally, biometric systems utilize machine vision for applications like facial recognition and patient identification, ensuring secure and accurate identification processes. The ability of these systems to process vast amounts of visual data quickly significantly improves diagnostic and operational efficiencies in healthcare settings.

Machine Vision vs. Computer Vision

Understanding the Key Differences

While the terms “machine vision” and “computer vision” are often used interchangeably, they serve distinct purposes. Machine vision specifically focuses on industrial applications such as quality control and process automation. In contrast, computer vision is broader, encompassing the ability of computers to interpret and understand visual information from the world around them, which includes concepts like image recognition, video analysis, and scene reconstruction. Understanding these differences is essential when selecting the right technology for specific applications.

Applications of Each Technology

Machine vision is primarily used in environments where visual inspection and automated processes are critical, such as manufacturing, packaging, and logistics. Computer vision, on the other hand, finds applications in various fields, including autonomous vehicles, security surveillance, and augmented reality systems. The choice between these technologies often depends on the requirements of the task at hand and the desired outcomes.

Choosing the Right System for Your Needs

Selecting the right machine vision or computer vision system involves several considerations, including the specific task, the complexity of the environment, budget constraints, and desired outcomes. Companies must assess their unique requirements and potentially conduct feasibility studies to determine the most suitable technology. Collaborating with experts in the field during this process can provide invaluable insights and ensure the implementation of a reliable and efficient system.

Future Trends in Machine Vision Technology

AI Integration and Enhanced Capabilities

The future of machine vision is closely tied to advancements in artificial intelligence. The integration of AI technologies will continue to enhance the capabilities of machine vision systems, making them more intelligent and adaptive. Enhanced algorithms will be capable of learning from vast amounts of visual data, enabling better anomaly detection, classification, and prediction. This evolution will lead to even more sophisticated applications, such as predictive maintenance and real-time decision-making in varied environments.

Market Trends and Industry Forecasts

Market trends indicate a growing demand for machine vision systems, driven by the need for automation in manufacturing and the increasing focus on quality assurance. Industries are anticipated to invest heavily in smart vision systems that integrate AI and machine learning, leading to improved efficiency, lower operational costs, and higher productivity. Continued advancements in sensor technology and processing capabilities will further propel the evolution of machine vision applications across different sectors.

Challenges and Opportunities Ahead

Despite the tremendous advancements, the machine vision industry faces challenges, including data privacy concerns, the need for continuous system training, and the complexity of integrating these systems into existing infrastructures. However, these challenges also present opportunities for innovation, as new solutions are developed to address them. The future will likely see enhanced collaboration between machine vision experts and industry leaders to foster advancements that aim to streamline processes while addressing industry-specific challenges.